If you’re using a lithium battery in your project, it’s important to understand the basics of Management System (BMS) . The BMS protection board for li-ion is responsible for monitoring and protecting the battery cells. It implements overvoltage, undervoltage, overcurrent and other protection functions through hardware solutions without software control.

It has protection settings which are described below. This allows the battery to be used in a wide range of products, from low-power standby devices to high-powered electric vehicles.

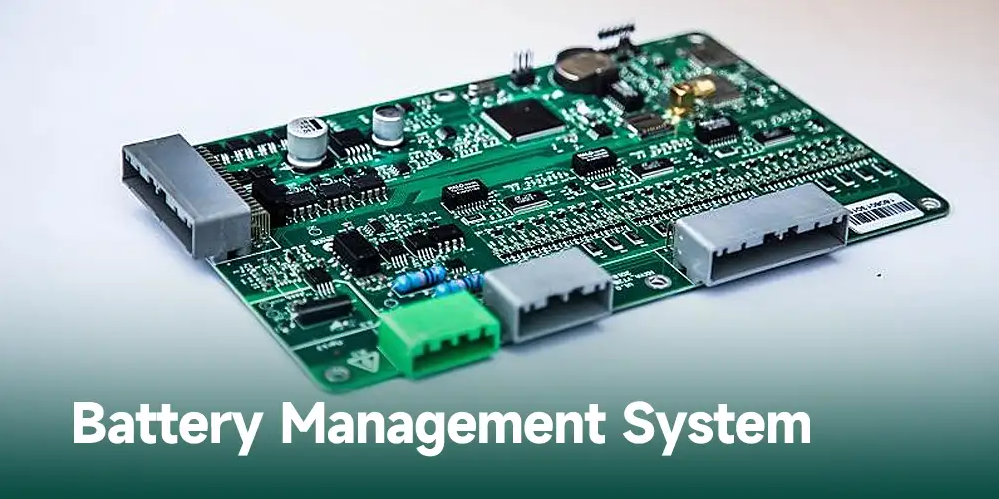

The BMS is typically implemented as a separate circuit board that is connected to the battery cells. It contains a microcontroller, sensors, and MOSFETs (Metal Oxide Field Effect Transistors) or other solid-state switches.

According to the structure, BMS can be classified into three categories: decentralized, centralized and integrated. but all BMSs perform the basic functions described below.

The core functions of BMS include:

Measuring

Cells voltage sampling

Cells temperature sampling

Pack’s total voltage sampling etc

The measurement function monitors the basic state of the battery in real time and is the basis of all functions of BMS. Without these measurements, all core algorithms and application functions of BMS are difficult to execute.

At present, BMS is still one of the core technologies of electric vehicles. Various OEMs, component suppliers, and scientific research institutes are continuing to increase research and development efforts. In the future competition of electric vehicles, having a battery management system with reliable performance and low price is one of the core competitiveness of electric vehicles.